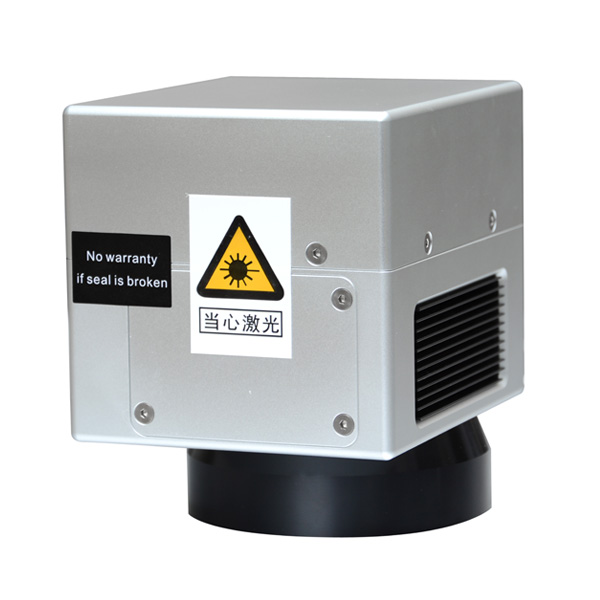

Galvo Scanner for 3D Printing and Additive Production

Galvo Scanner for 3D Printing and Additive Production

Blog Article

The Crucial Duty of Galvo Scanners in Accuracy Laser Positioning and Control

Galvo scanners, important to the precision and control of laser positioning, utilize high-speed revolving mirrors to achieve unrivaled precision in guiding laser light beams. What makes these devices vital in setups demanding careful laser operations?

Understanding Galvo Scanner Innovation

In the world of laser positioning, recognizing Galvo scanner technology is critical for attaining accuracy and efficiency. Galvo scanners, short for galvanometer scanners, use mirrors placed on galvanometers to direct laser beams with high accuracy and speed. These mirrors can quick, specific angular movements, enabling the laser beam of light to be guided to specific works with on a target surface area.

The functional concept of a Galvo scanner focuses on the galvanometer mechanism. A galvanometer converts electrical current into mechanical movement, triggering the mirror to pivot. By regulating the electric present, the mirror's angle is precisely adjusted, permitting specific laser positioning (galvo scanner). This is essential in applications such as laser engraving, medical imaging, and optical communication, where accuracy is crucial.

High-resolution encoders are typically integrated into Galvo scanners to offer real-time feedback on the mirror's position, guaranteeing very little discrepancy from the intended course. This responses loophole improves the scanner's accuracy and repeatability, making it an indispensable tool in industries calling for thorough laser support. Comprehending the complexities of Galvo scanner technology is hence essential for leveraging its complete capacity in advanced laser applications.

Devices of Laser Positioning

Efficient laser positioning relies on numerous advanced mechanisms to achieve high precision and precision. At the heart of these devices are galvanometer (galvo) scanners, which use rotating mirrors to route the laser beam of light with amazing speed and control. The core concept involves converting electric signals into precise angular motions through the galvo motor, which then readjusts the mirror's positioning to guide the laser beam of light to the wanted place.

Another vital component is the control system, which integrates feedback loops to continually keep an eye on and correct the laser's placement. This ensures marginal deviation from the target collaborates, enhancing the general precision. The use of innovative servo controllers permits real-time modifications, making up for any disparities that might occur throughout procedure.

These devices collectively make it possible for reputable and accurate laser positioning, vital for applications requiring rigid precision.

Advantages of Using Galvo Scanners

Galvo scanners use countless advantages that make them important in accuracy laser applications. The high-resolution responses systems incorporated right into galvo scanners ensure minute adjustments, therefore boosting precision and repeatability in laser positioning.

Furthermore, galvo scanners exhibit exceptional versatility. They can be set to implement complex scanning patterns and accommodate various beam of light sizes and shapes. This adaptability is crucial for tasks that demand elaborate laser paths, such as engraving comprehensive styles or carrying out fine procedures.

Integrity is another crucial advantage. Galvo scanners have a robust layout with very little moving parts, decreasing the likelihood of mechanical failing. This results in longer functional life-spans and lower upkeep costs, making certain constant efficiency over prolonged durations.

Additionally, the compact type variable of galvo scanners allows for easy combination right into diverse systems. Their little dimension does not endanger their performance, making them ideal for applications with spatial constraints.

Applications in Different Industries

Laser placing systems making use of galvo scanners have actually revolutionized various markets by boosting efficiency and precision. In the manufacturing industry, these systems are important to laser cutting and etching procedures, giving exceptional precision and rate. Automotive and aerospace sectors gain from the specific welding and exploration capacities of these systems, ensuring components meet strict quality standards.

In the medical field, galvo scanners are important in laser surgery and eye treatments, where precision is crucial for client security and successful outcomes. Dermatology and aesthetic treatments additionally count on these systems for tasks like tattoo removal and skin resurfacing. The electronics industry uses galvo scanners for PCB (Printed Circuit Board) manufacture, allowing the creation of intricate circuit patterns with high repeatability.

In addition, in the field of scientific study, galvo scanners are crucial in innovative microscopy methods, such as confocal and two-photon Our site microscopy, allowing scientists to capture high-resolution pictures of organic specimens. The art and enjoyment markets also utilize these systems in laser light programs and holography, creating vibrant visual experiences. On the whole, the convenience and accuracy of galvo scanners drive development and operational excellence throughout a wide variety of sectors.

Future Technologies and Patterns

As technological developments proceed to speed up, the future of galvo scanners in laser placing systems promises groundbreaking technologies and emerging fads. One significant fad is the combination of synthetic knowledge (AI) and artificial intelligence (ML) formulas to enhance the accuracy and flexibility of galvo scanners. These smart systems can predict and remedy deviations in real-time, causing higher accuracy and performance in Resources laser applications.

Another emerging fad involves the advancement of ultra-fast galvo scanners efficient in handling higher laser power and rate without endangering on precision. This advancement is specifically crucial for industries such as semiconductor production and clinical tool fabrication, where also minute mistakes can cause significant losses.

In addition, the miniaturization of galvo scanner components is anticipated to open up brand-new applications in wearable and portable devices (galvo scanner). Developments in micro-electromechanical systems (MEMS) modern technology are paving the means for more portable, yet extremely reliable, galvo scanners

Last but not least, boosted concentrate on sustainability and energy effectiveness will drive the development of environmentally friendly galvo scanner systems. By incorporating energy-efficient components and optimizing operational protocols, future galvo scanners will certainly not just boost efficiency yet additionally add to an extra lasting technological ecological community.

Verdict

Galvo scanners are essential in precision laser positioning and control because of their capability to convert electrical signals right into specific angular activities. Their sophisticated comments systems and servo controllers make certain real-time changes, giving constant performance and reliability. These attributes make galvo scanners important in sectors calling for thorough laser procedures, such as laser this content engraving and medical treatments. Future advancements guarantee further improvements, solidifying their important function in advanced technical applications.

Galvo scanners, important to the precision and control of laser positioning, use high-speed turning mirrors to achieve unparalleled precision in directing laser light beams. Galvo scanners, short for galvanometer scanners, utilize mirrors installed on galvanometers to direct laser beam of lights with high accuracy and rate. The high-resolution responses systems integrated right into galvo scanners make sure minute modifications, thus improving precision and repeatability in laser positioning.

Report this page